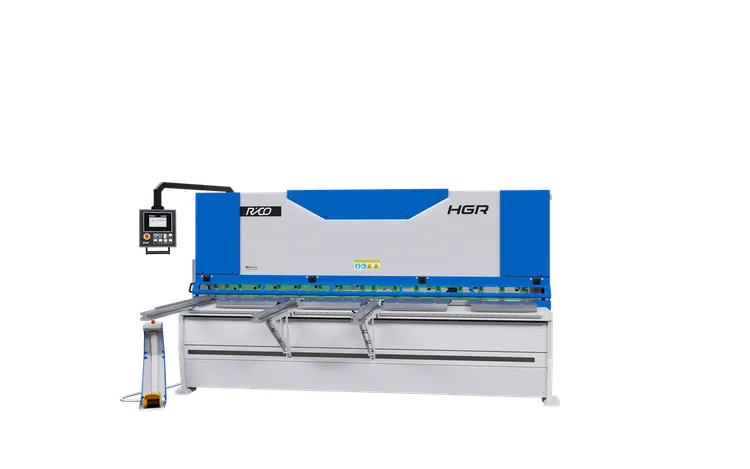

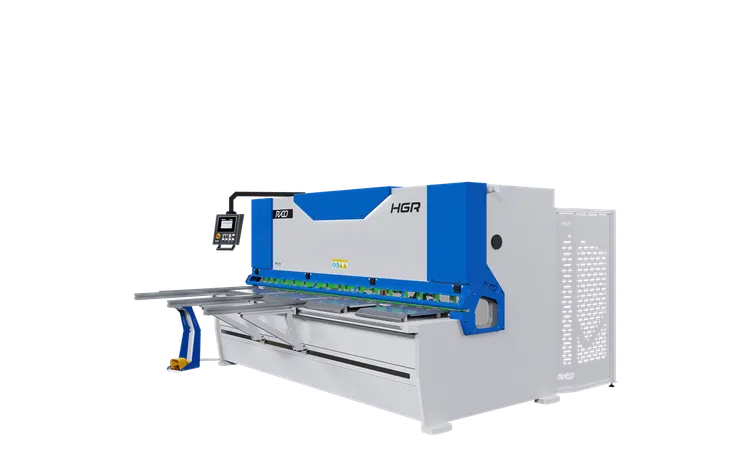

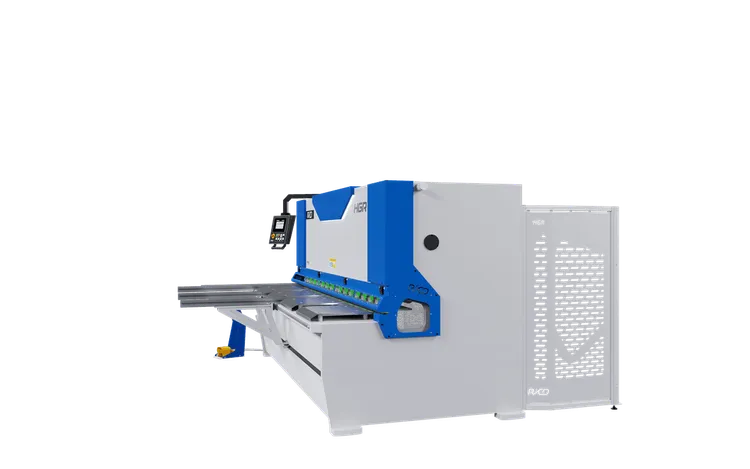

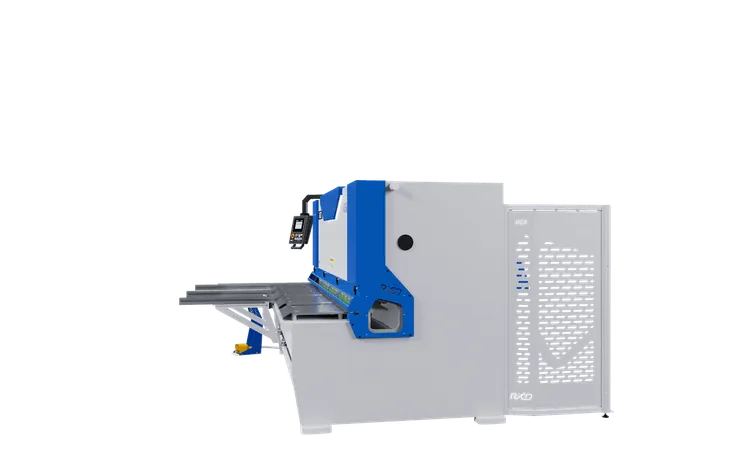

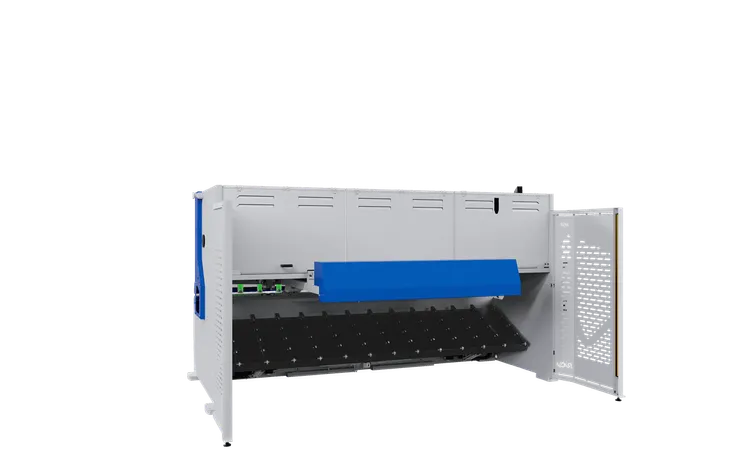

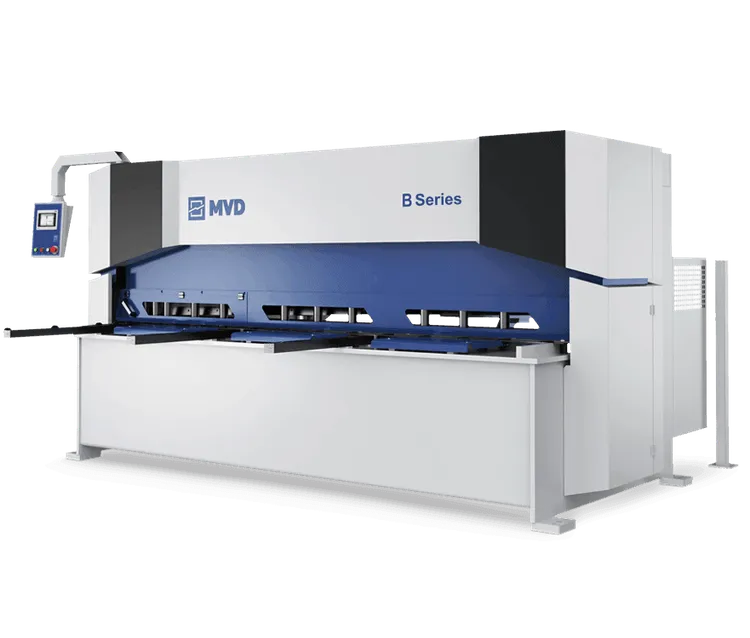

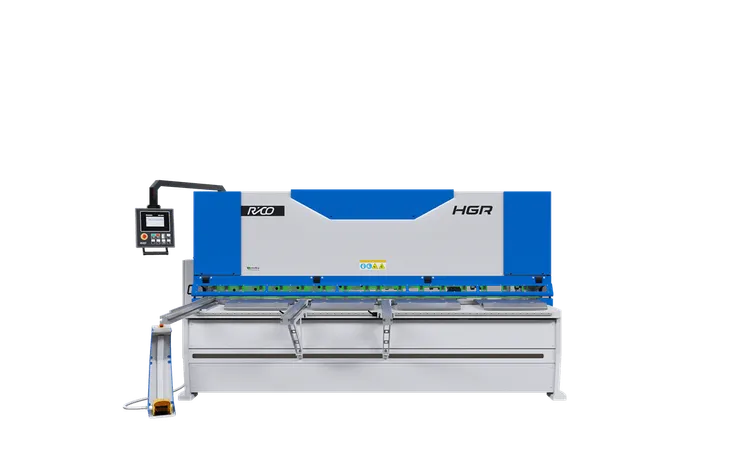

RICO HGR

Metal Cutting Guillotine

RICO HGR - A STRONG & RELIABLE GUILLOTINE

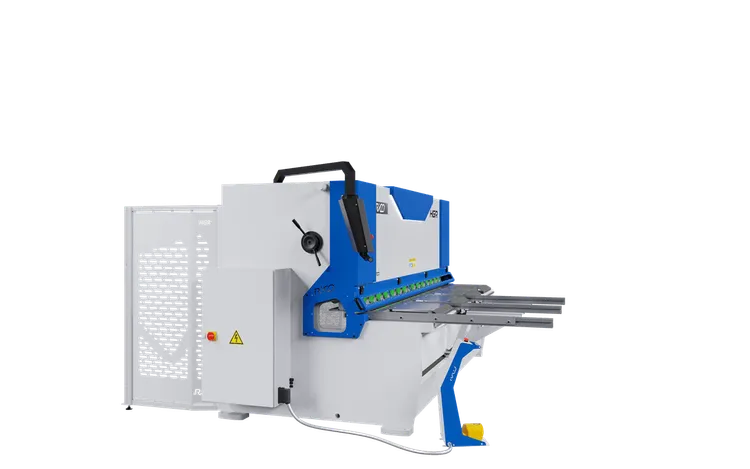

The RICO HGR hydraulic metal cutting guillotine is a 'high performance' hydraulic 'vertical' action,

metal cutting guillotine, with adjustable 'variable rake' to reduce the Helix on the cut piece of material.

The vertical cutting action, variable cutting 'rake' angle, HGR hydraulic metal cutting guillotine is the most effective and accurate system of metal sheet and plate cutting, when it is compared to alternative 'Swing Beam' guillotine cutting

METAL CUTTING SHEAR

'Standard' RICO HGR Guillotine - Technical Specification

Cut thickness capacities are calculated for material's with a tensile of 420N/mm2

Cut thickness & cut length are model dependant

- Cutting Thickness: 4 mm | 6 mm | 8 mm | 10 mm | 13 mm | 16 mm | 20 mm | 25 mm | 30 mm | 35 mm | 40 mm

- Cut Lengths: 1250 mm | 1550 mm | 2550 mm | 3050 mm | 4050 mm | 6050 mm

- Throat depth 135 mm to 215 mm (dependant on model)

- Rake Angle 1.5°/0.7° or 4°/2.5° (dependant on model)

- RAE back gauge retraction - backgauge retracts at commencement of a cutting cycle

- Material hold down jacks

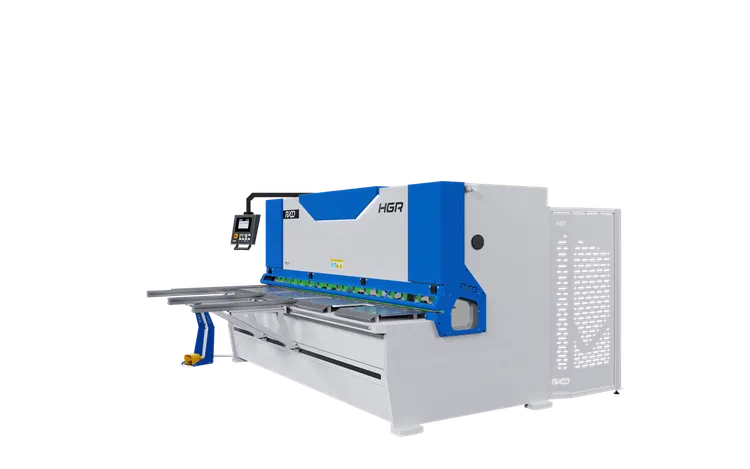

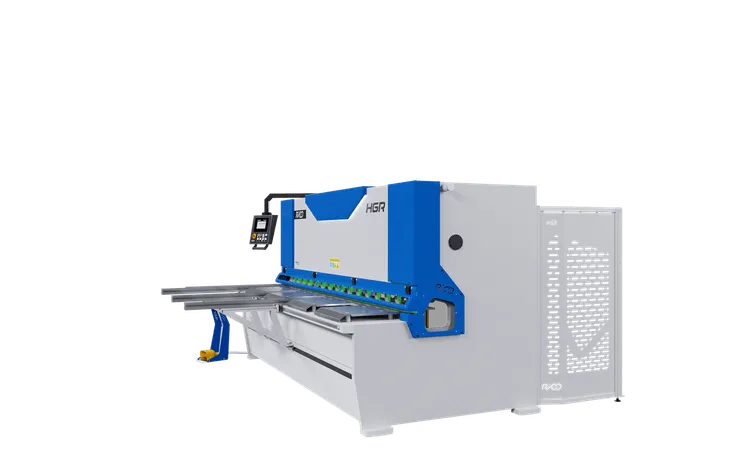

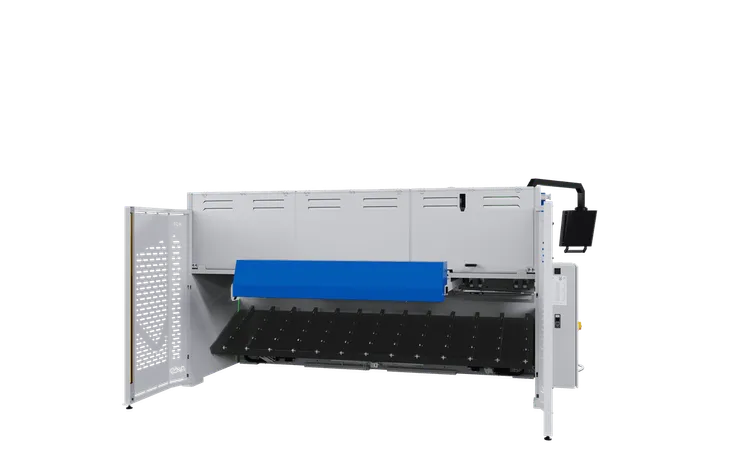

- Standard Machine & Back Gauge Controller. is the ELGO P40

- Hanging Swivel Machine Control

- Front table with roller balls

- Front Supports - (1) 1000 mm Squaring Arm | (1) 1000 mm Single Arm

- LED cutting area light, with shadow Line

- Fixed operator finger guard with view panels (lift up 1000 mm section)

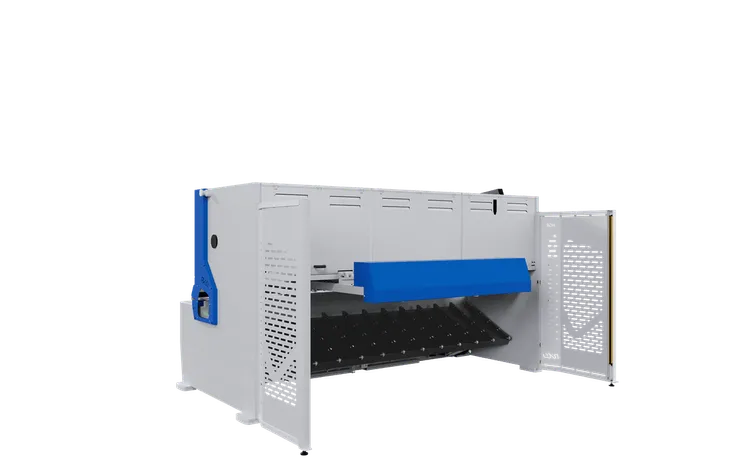

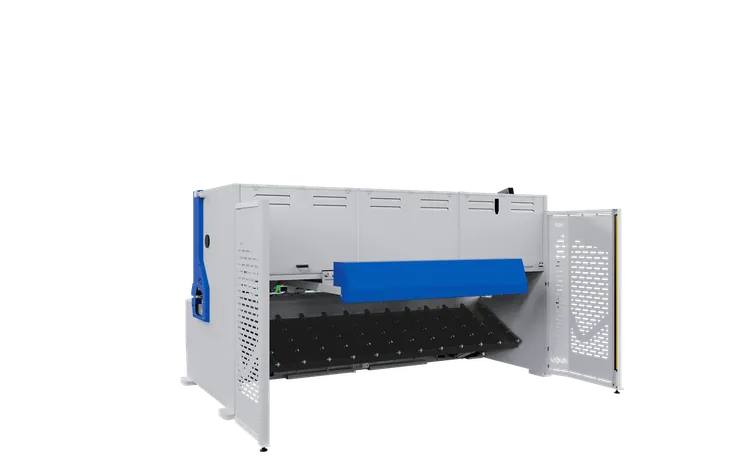

- Rear Entry Safety Barriers (Level IV)

- All RICO machines have an integrated 'StandBy' function, which automatically

stops the machines motor after 5 mins if inactivity

Extra 'Options'

- BGA Back Gauge in Lieu of the standard BGS back gauge | offering high speed positioning of 250 mm/sec

- Choice of Back Gauge controller ELGO P40T | DELEM DAC 360T | Cybtouch 8G

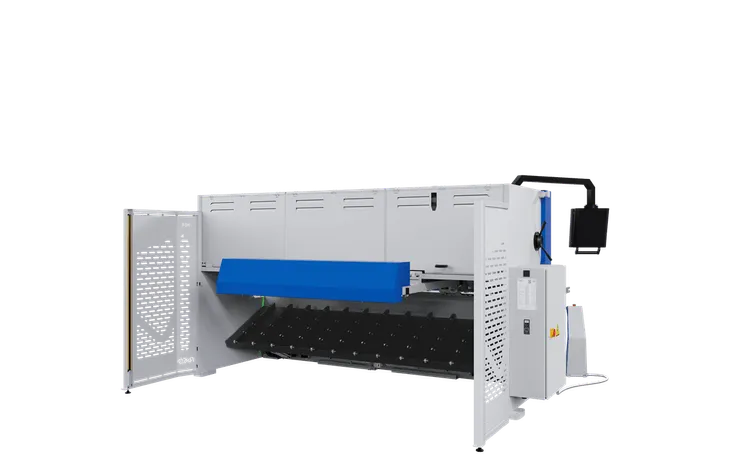

- Rear sheet support & cut material extraction | MAC1 | MAC2 | MAC 3 | MAC X

- Full Length Lift up operator finger guard with view panels

- Front feeder system - Allows the cutting of large sheets where a back gauge stroke of 1000 mm

is not sufficient for your cutting requirements - Anti Twist - Flat Cutting, a hydraulic system which exerts force onto the sheet to be cut

stopping the helix of the cut piece - RTS - Return to sender - allows the cut material to return directly to the operator

- FSE small cut pieces extraction pull out draw

- Frontal sheet cut material extraction