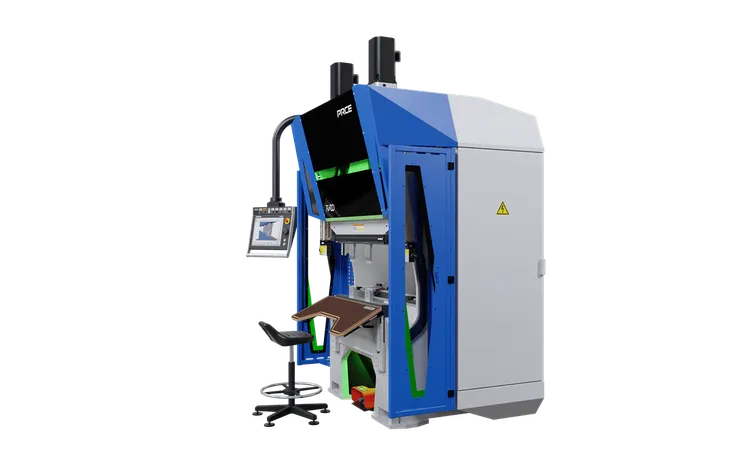

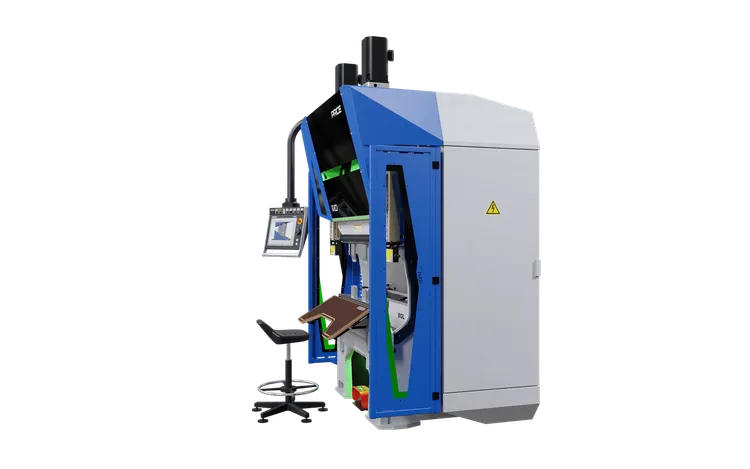

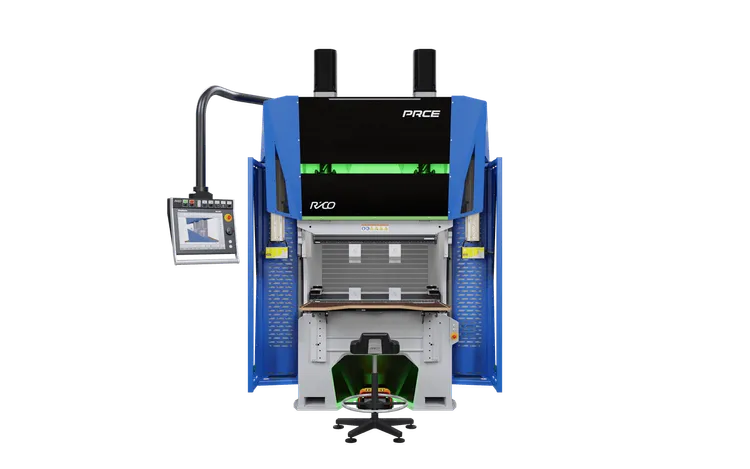

RICO PRCE CNC Electric Synchronised Press Brake

Synchronised Electric Press Brake

The RICO PRCE an Electric Synchronised Multi Axis Press Brake, offering substantially reduced metal bending cycle times, allied with reduced energy consumption (50% effective energy savings).

The RICO PRCE Electric -Servo Press Brake uses 2 specially developed 'high performance' ball screws driven by Servo Motors, via planetary gear units, to position each of the synchronised axis, [Y1+Y2].

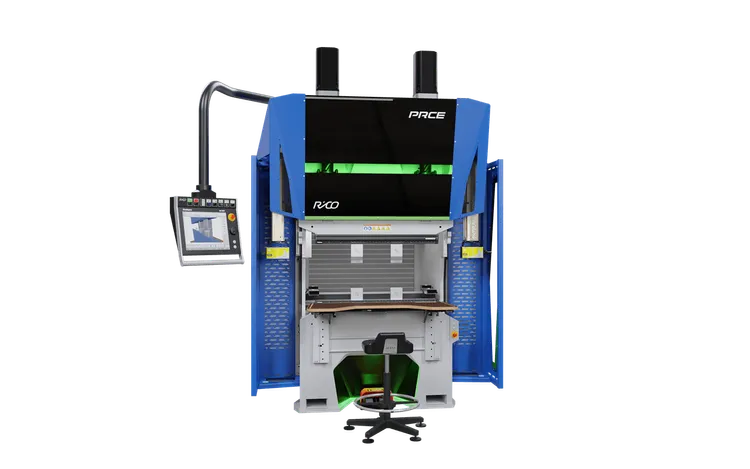

SYNCHRONISED ELECTRIC PRESS BRAKE

Standard Machine Technical Specification

- Tonnage capacities 40 Tons | 80 Tons

- Bend Lengths 1100 mm | 1600 mm | 2100 mm | 2600 mm | 3100 mm

- Standard 4 Automatic Axis [Y1+Y2+X+R]

- BGR Back gauge - Precise, robust box section

- Standard Controller is the DELEM DA-58T

- Hanging Swivel Machine Control

- Front Supports - SFS Sliding

- Frontal Operator Safety AKAS II-F

- Rear Entry Safety Barriers (Level IV)

- Promecam Style Top & Bottom tool clamping (Euro Style)

- Off Line Software - Profile TL

- All RICO machines have an integrated 'StandBy' function, which automatically

stops the machines motor after 5 mins if inactivity

Extra 'Options'

- BGR - Additional Back Gauge Axis [Z1+Z2+X5]

- ECO Boost - Increases the beam return speed

- LED tool Locator, assists the operator position parts in complex bending programs

- BTM Back Gauge 6 Automatic Axis X1+X2+R1+R2+Z1+Z2

- BTL Back Gauge 6 Automatic Axis X1+X2+R1+R2+Z1+Z2

- 3D CNC Graphic controls

- Manual Quick Clamping | Pneumatic | Hydraulic clamping systems